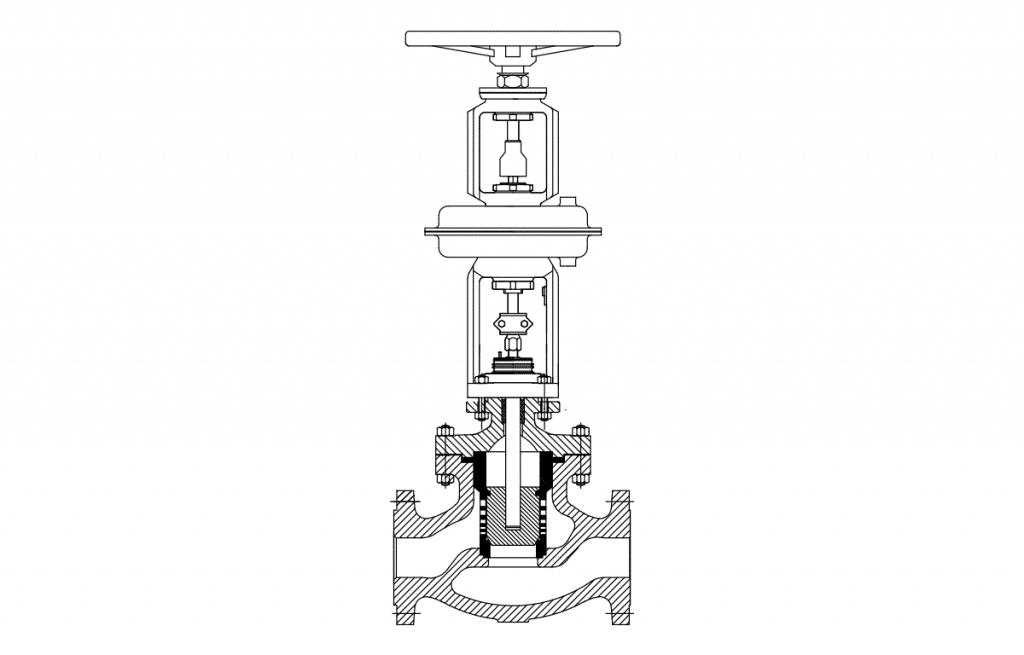

Globe Type Control Valve - E30C

This type Globe Valves are used for regulating and throttling at various pressures or flow rates and they can provide pressure and flow control as it can operate in semi-open positions. Control valves have a cage. It is a cylinder that is drilled and tightened between body and bonnet. Shape of the cage holes provide to control of pressure drop and noise.

Control Valves can be produced as balanced or unbalanced type. Balance is provided by holes on the disc. Vastas recommend unbalance type for 1” and 1 ½”.

Globe Type Control Valves are produced with steel body and API Trim No. 8 as standard, ends being flanged to ASME B16.5 or Buttwelding to ASME B16.25 and Face to Face Dimensions complying with ASME B16.10 standard. Mating Flanges (WN), Fasteners (2H & B7) and Gaskets (SWG) are supplied upon request. Vastas gaskets for sealing of flanged connections are made of non-asbestos materials and are fireproof even for 150 class, spiral wounded 316SS & Graphite or RJ type for higher classes.

Application Areas

Crude Oil Storage

Crude Oil Terminal

Crude Oil Pipeline

Natural Gas Pipeline

Fuel Pipeline

Fuel Storage

Tank Storage

LNG Terminal Plant

RMS

Refinery

Power Plant

Petrochemical Plant

Water Works

Hydrogen

Functions

ESDV - BDV - SDV - MOV - MAN - PROCESS VALVE SYTEMS

Vastas Figure E30C

Type

Globe Type Control Valve, Cage & Piston Disc

NPS

1"-24"

DN

25-600

Class

150-1500#

Features

ANSI B16.34 & BS 1873

Carbon Steel or Stainless Steel

Bolted Bonnet

Outside Screwed & Yoke

Rising Stem and Disc

Disc for Throttling and Open/Close

Soft or Metal to Metal Seat Faces

SWG or RTJ Gasket Between Body and Bonnet

Different Types of Stem Packing upon request

Standards

Design standard BS 1873 & API 623, in compliance with according to ASME B16.34 standards

Operators

» Manual Operated

» Electric Actuators

» Pneumatic Actuators

» Hydraulic Actuators